Build a Better Box Design Contest Results

The deadline for entries was June 1, 2020.

Sea turtles are endangered species; they need people’s help.

We put the eggs in Styrofoam boxes to protect them from poachers, animals and waves. But the boxes never biodegrade! In 2020, with our partners Sea of Change Foundation, we hosted a design contest to Build a Better Box for Sea Turtles https://www.youtube.com/watch?v=oOaSsLsmpCo

We received design ideas from people of all ages from all over the world. Watch this video to see the winners!

Round 1 of Field Testing

The Science Exchange Interns, Cora and Ellery, and Director Katherine built the 5 contestant boxes that the judges previously scored highest from

The coconut fiber box was taken out because it would not stay together. The 4 buildable boxes were tested in the field against the control boxes – 3 Styrofoam boxes. Out of curiosity we also tested 3 paint buckets with holes (commonly used in Mexico), a rice bag or “costal” (commonly used in Central America), and a wooden fruit crate with palm frond husk lining (our idea).

The guidelines for the design contest in the video found here https://www.youtube.com/watch?v=oOaSsLsmpCo were used in field testing.

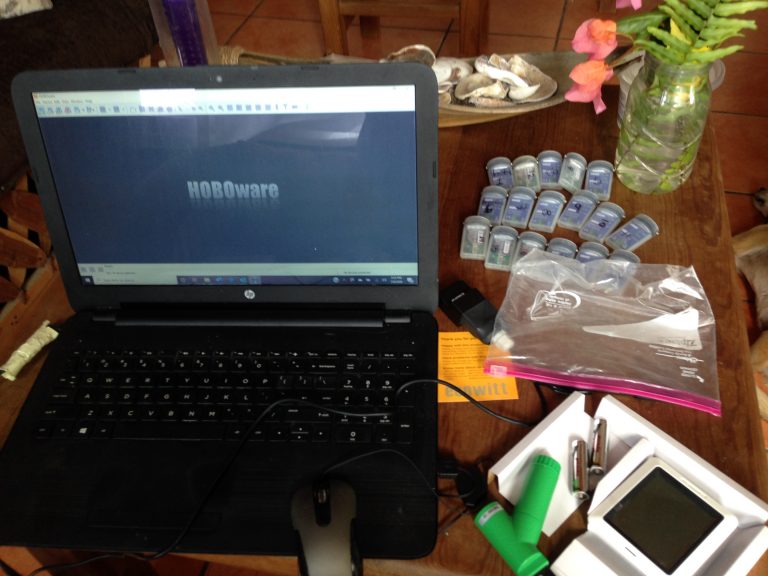

Following the San Pancho camp practices, 23 kg of moistened sand was added to each box with thermometer in the middle.

All 14 boxes were placed in the nylon lined box nursery tent for 45 days, the average incubation period for olive ridley sea turtles that nest here.

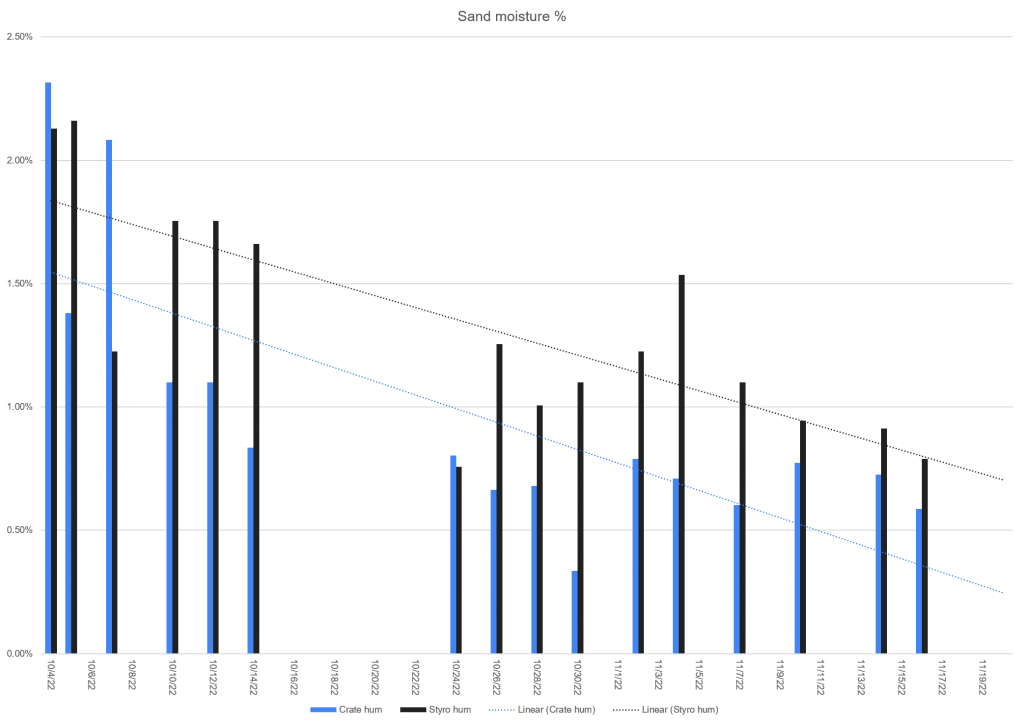

For sand moisture testing we periodically took moisture readings with the Teros-10 soil sensor.

Round 2 of field testing

A combination of several contest entries was tested in the next round – Phase II. The coconut palm fiber was attached inside the sphere and crate with the natural glue from the paper mache entries (vinegar, water, and flour) and cinnamon was be added as a natural insect repellent (suggested by a contestant). In this phase the schools and community centers were open so the kids helped us build them! Thanks to Trinity Niko and Karla De La Pena for helping build and test them and do outreach.

Watch the process in this video (translated subtitles are available through You Tubes language settings):

Results of Round 2

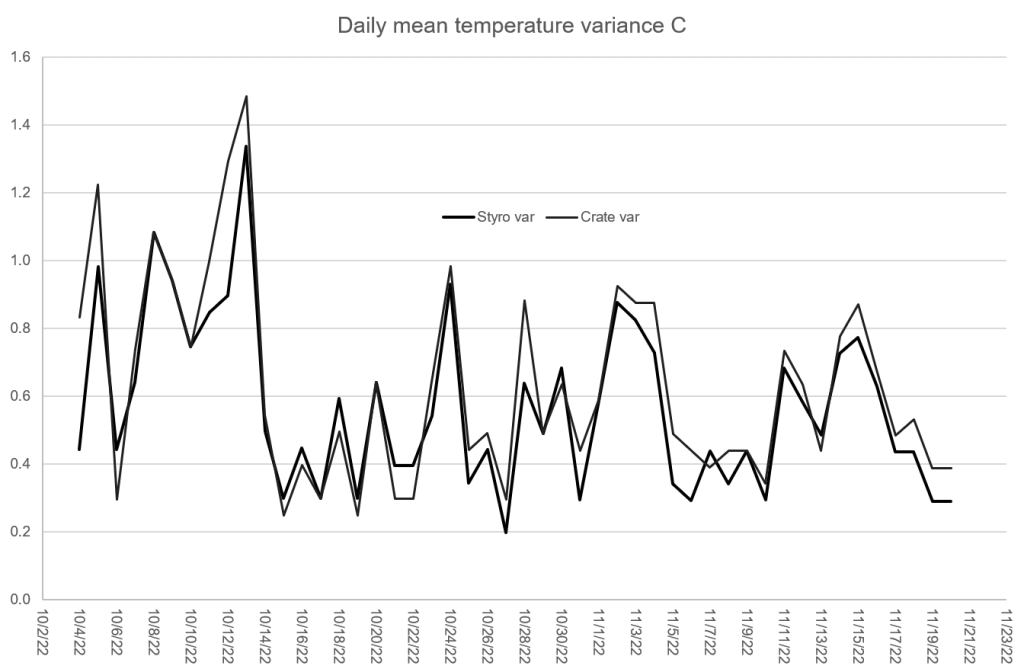

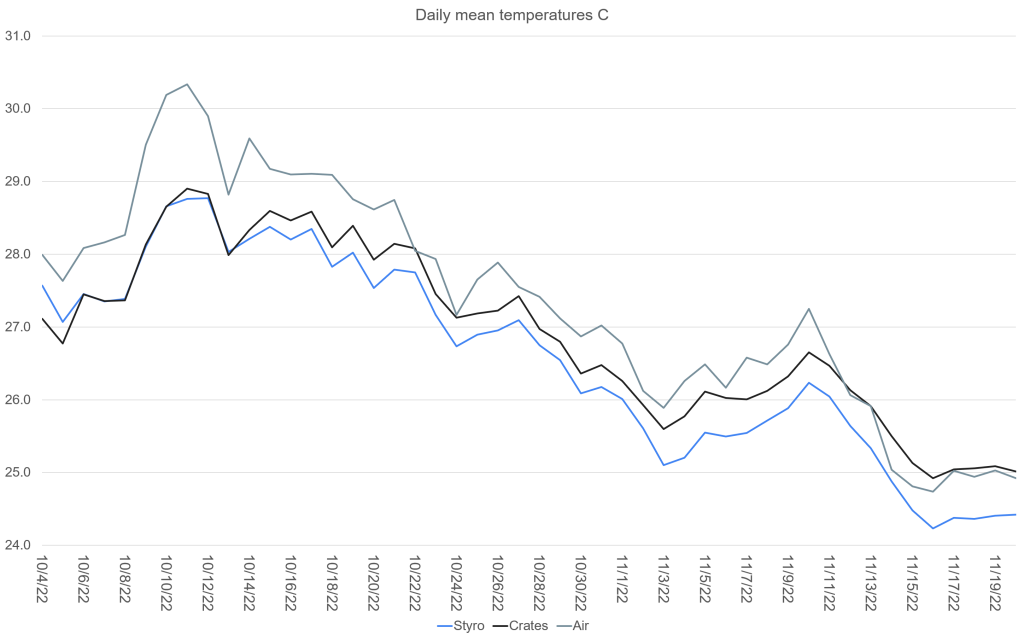

All three boxes maintained adequate sand temperatures for incubation (25-35 C), and the trials showed no differences in mean daily sand temperatures (Mann-Whitney tests p>0.05). However, daily max temperatures were higher in the crates and spheres by 6.5 C (p<0.05), and temperatures varied daily by an additional 3.5 C compared to polystyrene (p<0.05). This means the polystyrene performed better as an incubator in this hot region. In the fall of 2022, we improved the experiment by pairing vertically stacked, repurposed wooden fruit crates insulated with sustainable, locally-sourced coconut palm fiber and banana leaves and/or cotton cloth. These were compared with polystyrene boxes in a controlled interior environment. The spheres were eliminated because they took two hours to weave. We are excited to report that in this trial, there were no differences in daily mean temperatures (Mann-Whitney tests p>0.05). Daily max temperatures were higher in the crates (27.2 vs 26.9 C) (paired T-test p<05) but temperature variance was not different (p>0.05). Moisture was slightly lower in the crates by 0.5% (Mann-Whitney test p<0.05). However, these statistical differences are likely biologically irrelevant and within the range of instrument error.

There were no differences in daily mean temperatures (Mann-Whitney tests p>0.05)

There were no differences in daily temperature variance (Mann-Whitney tests p>0.05).

The difference in moisture levels was biologically irrelevant.

Vertically stacked fruit crates with coconut palm fiber, banana leaves, and cotton cloth.

Therefore, we believe we have developed an eco-friendly incubator to rival traditionally used polystyrene coolers. Testing with eggs is the proposed next phase. We recommend splitting clutches between each prototype so any differences in hatch success and hatchling fitness will be attributable to the incubator. Real-time monitoring and associated mitigation actions would prevent risks to the embryos during the next trial.

If you have questions please write to science_exchange@hotmail.com